Precision Steel Slitting Services

Tool King is widely admired for superb, tight-tolerance narrow coil slitting, a sought-after metal cutting technique from which myriad industries benefit. Beyond processing our own material, we are pleased to perform toll-slitting and re-slitting for OEMs, mills and distributors.

Capacities and applications for our cold rolled steel slitting procedures

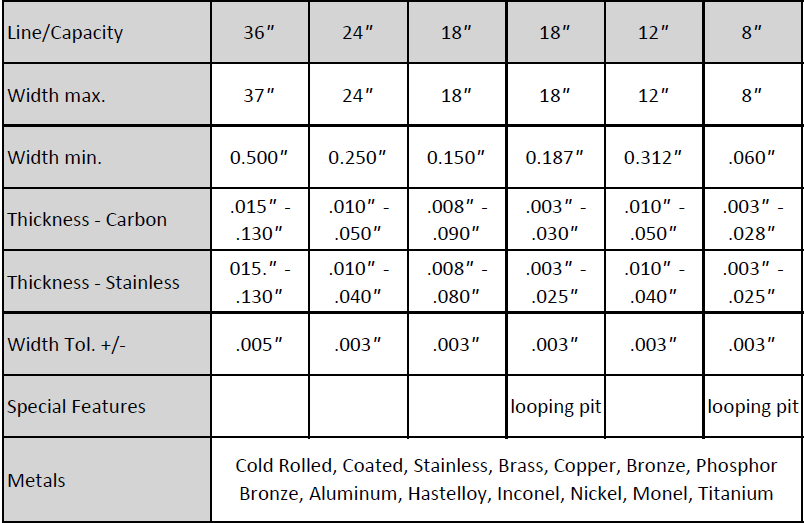

At Tool King, our slitting procedures use a wide-range of metals and we are happy to offer a variety of widths, thicknesses for both carbon and stainless steel, in addition to lines and capacities for our work.

Steel Slitting Capacities include:

Line and Capacity

For slitting with Tool King, the lines and capacities that we offer depend on your specific industry needs. Please read on for more information, and to find out which additional specifications can coincide with the line and capacity that you are looking for.

Carbon thickness

Tool King is happy to offer a range of thicknesses available for carbon used in our slitting process.

Stainless steel thickness

Tool King is happy to offer a range of thicknesses available for stainless steel used in our slitting process. Depending on your industry, processes and operations, the stainless steel thickness you’re looking for will vary.

Width Tolerance +/-

The Width tolerance of your product depends on other specifications. Please read on for more information on the specs offered from Tool King, and do not hesitate to contact us as you determine what you need.

Special features

As a special feature in our slitting process, we are happy to offer a looping pit for certain products. Looping pits are available for slitting with the following specifications:

- 18″ lines and capacities with a maximum width of 18″ and a minimum width of 0.187″, in addition to a thickness of .003″-.030″ for carbon or .003″ -.025″ for stainless when the width tol. is .003″

- 8″ lines and capacities with a maximum width of 8″ and a minimum width of .060″, in addition to a thickness of .003-.025″ for stainless and a width tol. of .003″

As always, Tool King welcomes you to contact us with any further questions that you may have about our product offerings.

Metals

Depending on your industrial process and your specific needs, you will require a specific metal to put through our slitting process.

Tool King offers a wide range of metals available for slitting:

- Cold Rolled

- Low carbon

- High carbon

- Annealed

- Pre-tempered spring steels

- Coated

- Stainless

- Brass

- Copper

- Bronze

- Phosphor Bronze

- Aluminum

- Hastelloy

- Inconel

- Nickel

- Monel

- Titanium

At Tool King, we are always here to answers your questions. We look forward to responding to product inquiries, and we can be reached by telephone at 847.537.2881. If you are looking to contact a member of the Tool King team directly, we invite you to please do so. We pride ourselves on our client support, and we look forward to speaking with you and answering your questions.