Steel Packaging & Handling Capabilities

Beyond traditional coil packaging (“ribbon” or “pancake”), we offer enhanced capabilities and benefits including…

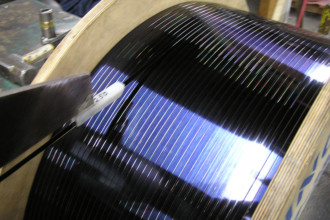

Oscillate Coil Winding (a.k.a. Traverse Coil Winding)

Oscillate wound coil is a great option for increased efficiency. In this method, slit coil is stagger-wound (similar to cloth thread or fishing line) over a wider spool. This is in contrast to the conventional ribbon-winding process, in which the coil is wound “edge flush.” Oscillate winding enables a much longer strip (est. 7x-15x) to fit onto an inside diameter (ID), thus reducing coil-changeover downtime, and increasing production runs. Our customers realize large gains in terms of:

- productivity rise exceeding 15% typically

- increased coil yields (i.e., far less head and tail loss)

- reduced scrap (fewer dollars wasted)

- reduced labor (fewer operators needed for coil mountings)

- reduced tool fatigue and increased tool life

- reduced injury risk; savings in terms of health care and worker compensation

Coil Bundles (a.k.a. “Cluster Coils”)

Beyond traditional individual slit coil “pancake” bundling, Tool King offers coil bundling. In this method, 8-10 mults are ribbon-wound recoiled on a fiber core, then banded as a single unit. The core can be loaded either “eye-to-sky” or “eye-to-side.” This package construction offers significant customers benefits…

- reduced material handling for increased efficiency

- enhanced worker safety – reducing injury and medical claims

- increased plant space