Traverse & Oscillate Coil Winding

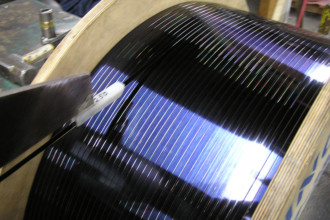

Oscillate Coil Winding, also known as Traverse Coil Winding, is an excellent solution for manufacturers in search of productivity gains and improved yields. Coils are slit according to the necessary specifications and wound in an oscillate fashion (much like thread or fishing line) onto spools. Throughout this process, many coils are welded together, from end-to-end, into one large coil. This is in contrast to the conventional ribbon-winding process, in which the coil is wound “edge flush.”

The goal of oscillate winding is to have a much longer length of metal strip wound onto an individual spool. This enables the longer strip (est. 7x-15x) to fit onto an inside diameter (ID), thus reducing coil setup time, increase production runs, and decreasing potential damage from excessive coil handling.

Tool King customers can expect large gains in the form of:

- productivity increases exceeding 15% typically

- increased coil yields (i.e., far less head and tail loss)

- reduced scrap (fewer dollars wasted)

- reduced labor (fewer operators needed for coil mountings)

- reduced tool fatigue and increased tool life

- reduced injury risk; savings in terms of health care and worker compensation