Metal & Steel Edging Process & Capabilities

A high-quality “edge-ucation” from Tool King

Tool King is especially unique as we are home to a team of experts and high-level machinery that work together to produce the highest quality galvanized steel edging.

Edging is a complex industrial process that is used in developing shapes for given metals. Edging is often necessary for steels used in a diverse array of industrial applications. Edges that have undergone the slitting process only can be limiting, while implementing a proper edging technique can allow the steel that you are working with to thrive. Appropriately edged steel can be more secure to the touch, and even contribute to product longevity, working better within the industrial services that they are meant to serve.

We offer a wide variety of coil edge shapes, especially across such a broad range of a gauge range so that your processed metals are smooth and ready for a wide-range of applications, allowing the team at Tool King to respond to a wide-range of clients and their needs.

Why steel edging?

Our edging and skiving services offer several valuable benefits, including:

- Faster and easier die feed-through

- Productivity enhancement

- Increased formability, particularly for hard steels

- Tighter width tolerances (+/- .001″)

- Assistance in the prevention of edge cracks

- Extended cycle-life of steel spring applications

- Improved customer safety and reduced product liability exposure

- Increased worker safety

- Decreased medical and worker compensation claims

Edging Capacities

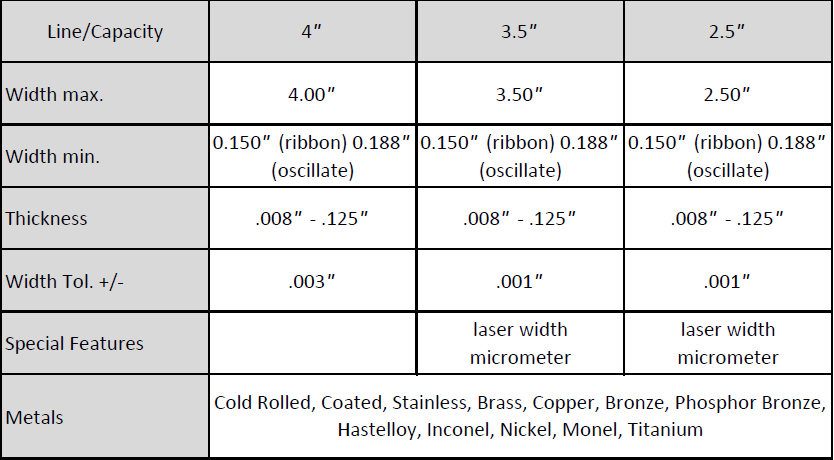

At Tool King, we are proud to accommodate diverse industries with our edged materials. Please read on for more information about the specifications that we offer, and to find out how these might work for you.

Edging Capacities available:

Special Edging Features

At Tool King, we offer special edging features that include laser width and micrometer features. Depending on the other specifications you will be putting into place during our edging process, a laser width or micrometer feature may be right for you.

Special edging features offered by Tool King include laser monitored width control for edging. Tool King can produce the coil edge profiles shown below:

| Tool King Edge Profiles | ||

|---|---|---|

|

#1 Round Edge * | Full round, R = ½ t, this type of edge enhances weld ability for production of tubing and bi-metal products |

|

#1 Square Edge * | Square edge, very accurate width, all slitter break removed |

|

#2 Mill Edge * | Edge (unprocessed) as normal mill-rolled, some burr |

|

#3 Slit Edge * | Standard slit edge - minimal burr |

|

#4 Rounded Edge * | a.k.a. Safety edge, semi-round corners less radius than #1 Round |

|

#5 Deburred Edge * | a.k.a. "Skived" - all burr removed; almost-square profile |

|

#6 Edge * | Semi-square (more radius than #1 Square) |

|

#7 Round/Square Edge ** | one side #1 Round; one side #1 Square (Tool King custom) |

|

#8 Bevel Edge ** | tapered both sides (Tool King custom) |

|

#9 Custom *** | your custom-engineered/proprietary profiles |

| * consistent with ASTM A505-00 (2005) ** per Tool King existing profiles *** per consultation with and approval of Tool King | ||

Metals

We pride ourselves on offering a wide-range of metals, and our experts are used to working with them.

Edging services use a variety of metals including:

- Cold Rolled

- Low carbon

- High carbon

- Annealed

- Pre-tempered spring steels

- Coated

- Stainless

- Brass

- Copper

- Bronze

- Phosphor Bronze

- Hastelloy

- Inconel

- Nickel

- Monel

- Titanium

At Tool King, we are always here to respond to product inquiries and we can be reached by telephone at 847.537.2881. You can also look at our contacts to get in touch with Tool King team members directly. We are happy to help you however we can, and we look forward to speaking with you!