Quality Steel Production & Policy

When it comes to quality, we’re unabashedly obsessive-compulsive…operating practices and controls often well beyond those demanded of our rigorous ISO 9001:2015 certification.

The Tool King Inc. Quality Policy

“Tool King is committed to supplying the finest products and services. We strive to fulfill and exceed our customers’ quality requirements and standards. Accordingly, we proactively and continuously improve our knowledge, skills, materials, processes, equipment, technologies and other resources.”

ISO Certification & Compliance

- ISO 9001:2015; ISO-certified since 1999

- Perry Johnson Registrars, Inc. (Certificate of Registration #C2017-00087-R1)

- Full periodic (semiannual) audits under the Registrar’s auspices

Steel Processing Abilities

Tool King has effectively supplied over 700 of the most quality, service and cost oriented customers, along with their most daunting applications. And while we’re a preferred steel vendor for many “blue chips,” we’re equally proud of our vital service to smaller OEMs and custom stampers. Customers know we’ll get the job done right — whether orders call for 1000 tons or 100 pounds.

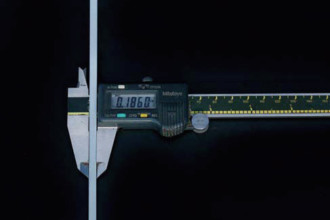

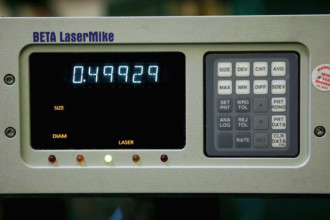

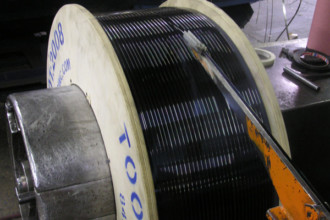

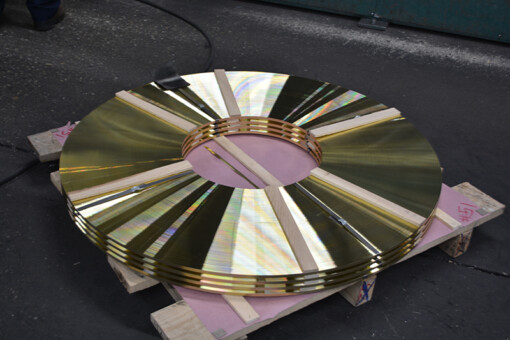

Tool King’s processing “toolbox” includes seven slitting lines and three edging machines, with electronic-laser tolerance monitoring. We can furnish slit coil in ribbon (“pancake”) and oscillate (traverse) wound form. Coil bundling (a.k.a. “cluster coil”) is also featured. Please visit our slitting, edging and packaging pages.

Metallurgical Capabilities

We furnish material certification to quality standards including ASTM, AMS, SAE, MIL-S and A2LA. In-house instrumentation includes Spectrometer, Rockwell Testers, Ball Punch Deformation Tester, Profilometer, Ultrasonic Micrometer, Magnetic Coating Thickness Gauge, Optical Comparator.

Steel Supply Services

Tool King’s Just-In-Time (JIT) programs are dependable and rapid – you’ll gain supply assurance, accelerated inventory turnover, maximized cash flow, freed-up production space, reduced material spoilage, along with a host of other valuable benefits. Major industries served include: springs, metal stampings (esp. multislide and fourslide), electronics, appliance, electrical, electronic, medical, automotive, hardware, military, aerospace, lighting, utensils, and picture frames. Based near Chicago, we service customers throughout the U.S., Canada, and in Latin America, Asia, Europe and the Middle East.

Solid, longstanding partnerships with trusted mills – domestic and foreign – engender supply breadth and depth, dependability and cost competitiveness.

Strategic Advantages for Steel Processing & Customer Fulfillment

Each year, comprehensive and detailed satisfaction questionnaires are submitted to the fifty of the company’s customers. These analyses are industry-comparative and incorporate sixteen performance metrics covering various aspects of quality, service, delivery and value. This data is analyzed to determine further opportunities for our performance maximization. Tool King offers rare, “quantum leap,” strategic benefits including:

Manufacturing Efficiencies and Savings

Customers often accrue substantial savings in terms of decreased labor costs (direct and indirect), faster production cycles, reduced equipment expenses, and accelerated cash flow.

- Our rare edging capabilities can reduce or eliminate certain of your manufacturing functions (i.e., chamfering, tumbling, grinding, filing, beveling).

- Our super-tight tolerances can foster faster and easier die feed-thru, enhancing your productivity.

- Our “best-of-class” close-tolerance slitting and edging may help improve the quality and speed of your welding operations.

New Marketing & Sales Potential

Current vendors’ processing limits may be unnecessarily constraining your company’s manufacturing potential and product lines. Tool King’s ultra-narrow coil widths and numerous edge options may enable you to offer new, smaller and/or more sophisticated products. This value-adding may substantially enhance your firm’s market share, revenues, profitability, and brand value.

Employee & Customer Safety

With our breadth of edging alternatives (i.e., “safety”, round, deburred) you may gain:

- improved customer safety; reduced product liability exposure and expenses

- increased worker safety; decreased medical and worker compensation claims